タキカワのカスタマーサポート

タキカワのカスタマーサポート

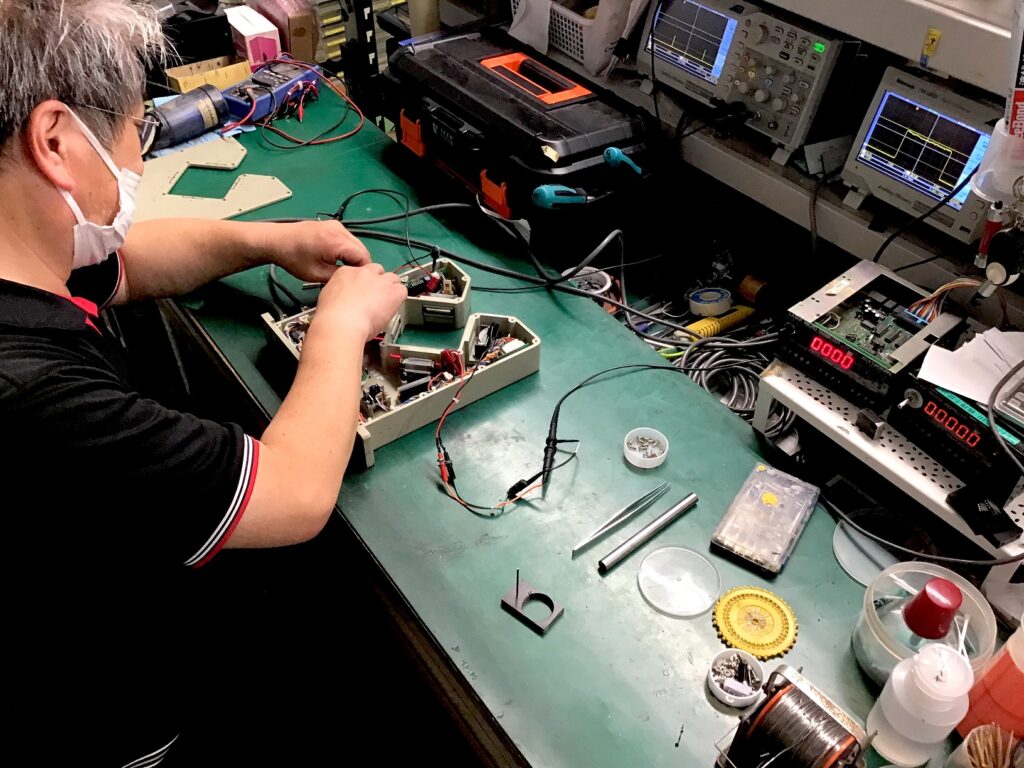

タキカワエンジニアリングでは、製品を長くご愛用いただけるように、サポート体制を整えております。

故障時の修理はもちろん、定期的なオーバーホールやご使用中に感じた不安の解消まで、お客様をトータルにサポートいたします。

迅速できめ細やかな対応、費用はできる限りリーズナブルに、をモットーにしておりますので、どうぞお気軽にお問い合わせください。

サポートメニュー

サポートメニュー

以降は、弊社製品をご使用中のお客様向けのコンテンツになります。

トラブルシューティング

機器ごとのトラブルに対する対処方法をご紹介しています。

メンテナンス

各機種のメンテナンスサイクルや方法についてご案内しています。

製造中止/サポート終了モデルについてもこちらからご確認いただけます。

よくある質問

弊社に多く寄せられるご質問の内容を、FQA形式でご紹介しています。

修理依頼

修理のご依頼に必要な用紙をダウンロードできます。

梱包発送時の注意点などについてもご確認ください。

ソフトウェア

弊社製品で使用するソフトウェアをダウンロードできます。